engineering

PROVIDING A WIDE RANGE OF PRODUCTS AND SERVICES.

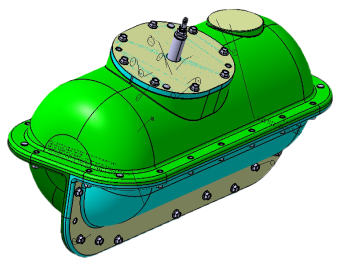

A WORLD LEADER IN THE DESIGN, DEVELOPMENT AND MANUFACTURING

OF ADVANCED COMPOSITES FOR THE AERONAUTIC, SPACE AND DEFENSE INDUSTRIES

what we do

- Part design/build or build-to-print composite manufacturing Engineering

- Process design and capture in robustly defined manufacturing processes (this means production documentation composition, compiling and tracking)

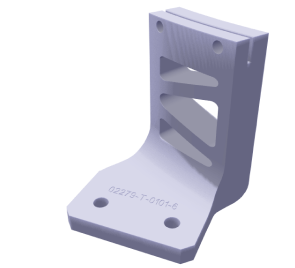

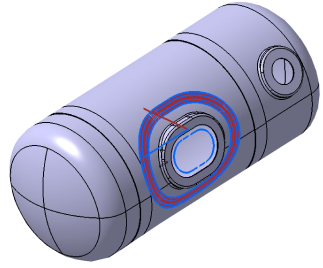

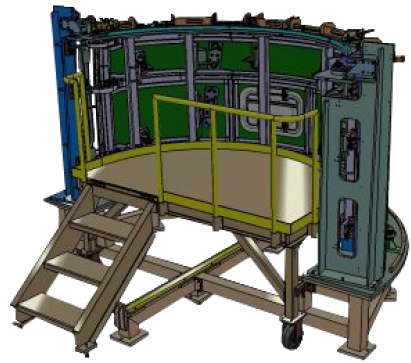

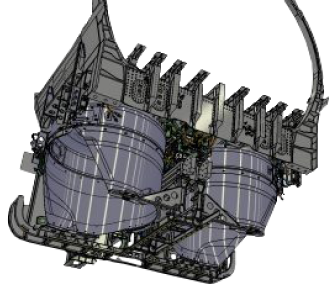

- Tool design, build and prototyping

- Production support and continuous improvement of live processes

- Customer technical liaison and communication (the latest in video conferencing and data sharing – portals, FTP, Zoom. MS TEAMs, WebEX all supported)

How we do it

- Design processes taking advantage of the latest techniques in composite fabrication - hand layup (prepreg, dry fabric/RTM), wet and tow-preg filament winding, both in and out of autoclave curing

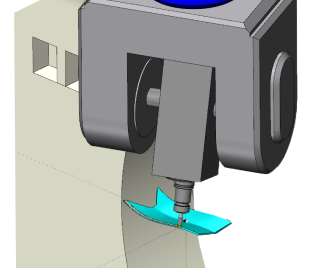

- Full service tool design for trim, drill and profile machining of cured composite laminate – including 5-axis processing with the latest in cutting tool technology baked-in

- Provide customer visibility of the process development through the entire start-up cycle – from contract award, process design and tooling build, prototyping and first article fab

- Production support and continuous improvement of live processes

- SNA Engineer-to-Customer Engineer correspondence and coordination on cost-saving process improvements throughout the production life-cycle

what tools we use

- Dassault Catia advanced CAD and analysis for part and tooling design [plus translators to allow for CAD data exchange with any contemporary CAD package]

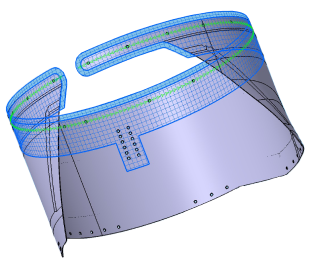

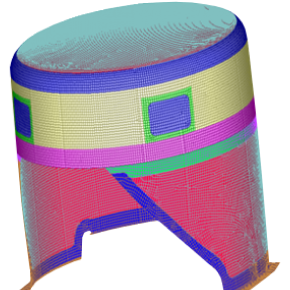

- FiberSIMM for detailed composite design and precise ply layout and control

- LaserGuide (from Assembly Guidance) and Virtek LaserEdge systems/software for programming of laser guided ply layup

- Lectra’s Diamino and Formaris for programming of automated ply cutting and optimized ply nesting

- MasterCAM for automated CAM CNC programming of 5-axis and 3-axis trim/drill and advanced 5-Axis Morph profile milling - as well as for CMM and automated NDI motion control

- FIberGraphix for automated CAM CNC programming of 4-axis filament winding

- Verisurf CMM inspection programming

- Markforged’s Eiger 3-D printing software for 3-D printing of tooling components

engineering expertise

Engineering

Disciplines

- Electrical

- Mechanical

- Industrial

- Materials

Technical

Disciplines

- Industrial Mechanics

- Manual and CNC Machinists

- CNC Programmers

- Electricians

- Non-Destructive Inspection Technicians (Level I, II and III's)

design and analysis

nastran/femap for:

Tooling and part design (composites and metals).

Our servives include:

- Analysis of quasi-isotropic and anisotropic materials.

- 2D (shell) and 3D (solid) analysis.

- Structural Linear and non-linear analysis for static and transient issues.

- Structural Dynamics (Modal, Harmonic, Spectrum, etc).

- Buckling (linear and non-linear) and Fatigue testing/analysis.