stelia north americaproducts

PROVIDING A WIDE RANGE OF PRODUCTS AND SERVICES.

A WORLD LEADER IN THE DESIGN, DEVELOPMENT, AND MANUFACTURING

OF ADVANCED COMPOSITES FOR THE AERONAUTIC, SPACE, AND DEFENSE INDUSTRIES

SPACE

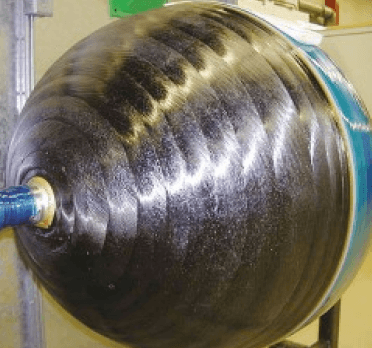

pressure vessel

- CNC controlled wet and towpreg winding

- Up to 1.2 meters in diameter

- Typically glass, Kevlar or graphite tow (T1000 & T800) in epoxy resin

reflector

- Satelite Panels and Reflectors

Space Station

- Different structures (60) for the Shuttle fleet and the ISS Mobile Servicing System

Carbon tubes

- Carbon tubes for RADARSAT-2 Antenna

- Deployment system built in 2001-2002 for AEC A

Defense

F-35

- Layup

- 5-Axis Machining

- Fuselage Panels

- 100% NDI

Services

Services to customers

- Design & Analysis

- Tooling Design & Manufacturing

- R&D and Prototyping

- Manufacturing

- Hand Lay up

- Filament Winding

- LCM

- Compression Molding

- Automated Fiber Placement (AFP)

- Assembly

- Finishing

- Non Destructive Inspection

- Testing

aeronautics

Dehavilland q-400

- Nose compartment

- Leadind Edges

- Flap shrouds

- Landing Lights

- Wing Tips

- Ice Shields

- Fairing

atr-72

- Flaps ATR 72

- Flap Skins ATR 42

boeing 787

- Environmental Control Systems Ducts

Spirit B 787

- Layup

- 5 Axis Machining

- 96 Structural Components for Section 41 Fuselage

AW-101

- Layup

- Assembly

- Sponsons

De-Icing Ducts for B747, B767 and B777

- Towpreg Winding

- Machining

- Assembly

Cargo light

- Layup

- Assembly

- Finishing

- High Production Rate (1000+ per month)

- Ready to install

AIRBUS A318-319-320-321

- Precooler Ducts (V2500 engine)

- Layup

- Insulation

- All parts are submitted to pressure testing and ultrasonic inspection (A-Scan)

STELIA Aerospace North America Inc. specializes in the design, development and manufacture of advanced composite structures for the aeronautic, defence and space markets. It is supported by manufacturing plants, environmental testing and prototyping establishments. SNA supplies components to major aeronautic, space and defense companies.

The wide range of products include: leading edges, fairings, radomes, structural panels, flaps, sponsons, landing gear doors, ducting (engine, anti-icing, ECS), pressure vessels, stringers, struts, launch tubes, satellites structures (antenna, reflectors, solar panel substrates).

Our core technologies include hand lay-up with autoclave/oven curing, filament winding, liquid composite moulding, compression moulding, CNC machining, and Automated Fiber Placement (AFP). Design and analysis software includes CATIA V5, Nastran and Fiber Sim.